When Compared To Sulfuric Acid How Strong Are Carboxylic Acids

Abstract

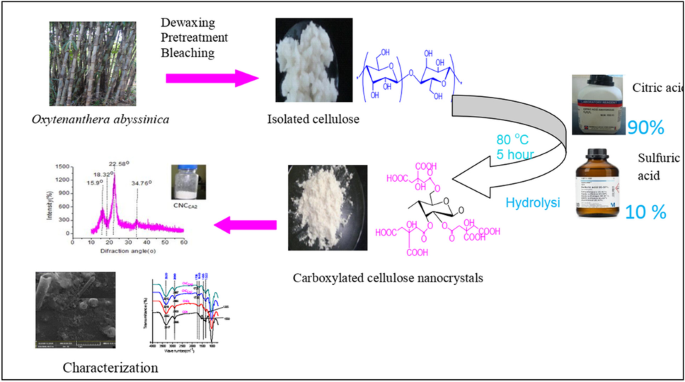

Acrid hydrolysis, which uses concentrated mineral acids to produce cellulose nanocrystals (CNC), is expensive, overdegrades the cellulose cloth, and is hazardous to human being and the environment. Thus recently, inquiry has concentrated on using organic acids to produce CNC for economic and environmental concerns. This study used citric acid anhydrous (85–100 wt%) with a smaller amount of sulfuric acid (0–15wt%) as a goad to prepare carboxylated nanocrystals from Oxytenanthera abyssinica cellulose. The highest yield (89.7%) was obtained with a reaction status of a 9:1wt% ratio of citric acid anhydrous to sulfuric acid, temperature (80 °C), and reaction time (5 h). The carboxyl functionalization of cellulose nanocrystals was affirmed through the conductometric titrimetric method and Fourier transform infrared spectroscopy. The conductometric titration showed a maximum carboxylate concentration of 0.75 ± 0.08 mmol/g; this gave the CNC stable dispersibility. Based on scanning electron microscopy characterization, mostly spherical-similar shapes of carboxylated cellulose nanocrystals were obtained. The dynamic light scattering assay showed that the particle possesses a particle size of 68.06 ± i.05 nm with a maximum absolute value zeta potential of -33 mV. The 10-ray diffraction analysis found cellulose crystallinity in the lx.37 to 81.iii% range. The thermal gravimetric analysis showed that rapid mass loss occurred betwixt 245 and 400 °C, with a maximum weight loss of 95%. Introducing the carboxylic group from citric acid anhydrous to cellulose can heighten the application of cellulose. Since the carboxylic groups are simultaneously introduced to the surface of cellulose during the hydrolysis process, it has the advantage of reducing the amount and chemical prices that toll for serial and long-pace surface functionalizing reactions. Citric acrid could be hands recovered through a rotary evaporator, and since it is obtained from fruits, the carboxylic CNC formed has lower toxic risks. These environmentally friendly, sustainable, and nontoxic backdrop gave the produced carboxylic CNC high potential application for the production of biofilms, food packaging cloth, UV protection, drug delivery, and new bio-based nanomaterials.

Graphical Abstract

Data availability

All data generated or analyzed during this written report are included in this newspaper.

References

-

Kwok TT, Fogg DN, Realff MJ, Bommarius AS (2017) Applying direct yellow 11 to a modified Simons' staining assay. Cellulose 24:2367–2373

-

Wang H, Du H, Liu K, Liu H, Xu T, Zhang Southward, Chen X, Zhang R, Li H, Xie H (2021) Sustainable training of bifunctional cellulose nanocrystals via mixed H2SO4/formic acid hydrolysis. Carbohydr Polym 266:118107

-

Chen L, Zhu J, Baez C, Kitin P, Elderberry T (2016) Highly thermal-stable and functional cellulose nanocrystals and nanofibrils produced using fully recyclable organic acids. Greenish Chem 18(13):3835–3843

-

Ciolacu D, Ciolacu F, Popa VI (2011) Baggy cellulose—structure and label. Cellul Chem Technol 45(i):thirteen

-

Mokhena TC, John MJ (2020) Cellulose nanomaterials: new generation materials for solving global bug. Cellulose 27(3):1149–1194

-

Reid MS, Villalobos M, Cranston ED (2017) Benchmarking cellulose nanocrystals: from the laboratory to industrial product. Langmuir 33(7):1583–1598

-

Wang Q, Zhao X, Zhu J (2014) Kinetics of potent acid hydrolysis of a bleached kraft pulp for producing cellulose nanocrystals (CNCs). Ind Eng Chem Res 53:11007–11014

-

Yu H, Qin Z, Liang B, Liu Northward, Zhou Z, Chen L (2013) Facile extraction of thermally stable cellulose nanocrystals with a high yield of 93% through hydrochloric acrid hydrolysis nether hydrothermal conditions. J Mater Chem 1:3938–3944

-

Camarero ES, Kuhnt T, Foster EJ, Weder C (2013) Isolation of thermally stable cellulose nanocrystals by phosphoric acid hydrolysis. Biomacromol xiv:1223–1230

-

Sharma PR, Joshi R, Sharma SK, Hsiao BS (2017) A uncomplicated arroyo to set up carboxycellulose nanofibers from untreated biomass. Biomacromol 18:2333–2342

-

Cheng Chiliad, Qin Z, Chen Y, Liu J, Ren Z (2017) Facile i-pace extraction and oxidative carboxylation of cellulose nanocrystals through hydrothermal reaction by using mixed inorganic acids. Cellulose 24:3243–3254

-

Wang DC, Yu HY, Qi D, Wu Y, Chen Fifty, Li Z (2021) Confined chemical transitions for directly extraction of conductive cellulose nanofibers with graphitized carbon shell at low temperature and force per unit area. J Am Chem Soc 143:11620–11630

-

Xie H, Du H, Yang X, Si C (2018) Recent strategies in preparation of cellulose nanocrystals and cellulose nanofibrils derived from raw cellulose materials. Int J Polym Sci 2018:7923068. https://doi.org/ten.1155/2018/7923068

-

Ji JH, Xiang Z, Qi H, Han T, Pranovich A, Song T (2019) Strategy towards one-step grooming of carboxylic cellulose nanocrystals and nanofibrils with high yield, carboxylation and highly stable dispersibility using innocuous citric acrid. Green Chem 21(8):1956–1964

-

Jiang J, Zhu Y, Jiang F (2021) Sustainable isolation of nanocellulose from cellulose and lignocellulosic feedstocks: Recent progress and perspectives. Carbohydr Polym 267:118188

-

Liu W, Du H, Liu H, Xie H, Xu T, Zhao 10, Liu Y, Zhang X, Si C (2020) Highly efficient and sustainable preparation of carboxylic and thermostable cellulose nanocrystals via FeCl3-catalyzed innocuous citric acid hydrolysis. ACS Sustain Chem Eng eight(44):16691–16700

-

Håkansson KM, Autumn AB, Lundell F, Yu S, Krywka C, Roth SV, Santoro G, Kvick M, Prahl Wittberg Fifty, Wågberg L (2014) Hydrodynamic alignment and assembly of nanofibrils resulting in strong cellulose filaments. Nat Commun 5(1):1–x

-

Thomas B, Raj MC, Joy J, Moores A, Drisko GL, Sanchez C (2018) Nanocellulose, a versatile green platform: from biosources to materials and their applications. Chem Rev 118(24):11575–11625

-

Chen W, Yu H, Lee South-Y, Wei T, Li J, Fan Z (2018) Nanocellulose: a promising nanomaterial for advanced electrochemical free energy storage. Chem Soc Rev 47(8):2837–2872

-

Kim JH, Lee D, Lee YH, Chen W, Lee SY (2019) Nanocellulose for free energy storage systems: beyond the limits of synthetic materials. Adv Mater 31(20):1804826

-

Miao C, Du H, Parit M, Jiang Z, Tippur HV, Zhang Ten, Liu Z, Li J, Wang R (2020) Superior scissure initiation and growth characteristics of cellulose nanopapers. Cellulose 27(6):3181–3195

-

Zhou Y, Fu S, Zheng L, Zhan H (2012) Outcome of nanocellulose isolation techniques on the formation of reinforced poly (vinyl alcohol) nanocomposite films. Express Polym Lett 6(x):794–804

-

Du H, Liu W, Zhang M, Si C, Zhang X, Li B (2019) Cellulose nanocrystals and cellulose nanofibrils based hydrogels for biomedical applications. Carbohydr Polym 209:130–144

-

Lin Westward, Chen D, Yong Q, Huang C, Huang S (2019) Improving enzymatic hydrolysis of acid-pretreated bamboo residues using amphiphilic surfactant derived from dehydroabietic acrid. Bioresour Technol 293:122055

-

Abouzeid RE, Khiari R, El-Wakil Northward, Dufresne A (2018) Current country and new trends in the use of cellulose nanomaterials for wastewater handling. Biomacromol xx(2):573–597

-

Dong YD, Zhang H, Zhong GJ, Yao K, Lai B (2021) Cellulose/carbon composites and their applications in water treatment–a review. J Chem Eng 405:126980

-

Hubbe MA, Tayeb P, Joyce M, Tyagi P, Kehoe M, Dimic-Misic K, Pal L (2017) Rheology of nanocellulose-rich aqueous suspensions: a review. BioResources 12(4):9556–9661

-

Liu C, Du H, Dong 50, Wang X, Zhang Y, Yu G, Li B, Mu X, Peng H, Liu H (2017) Backdrop of nanocelluloses and their application as rheology modifier in paper blanket. Ind Eng Chem Res 56(29):8264–8273

-

Clarkson CM, El Awad Azrak SM, Forti ES, Schueneman GT, Moon RJ, Youngblood JP (2021) Recent developments in cellulose nanomaterial composites. Adv Mater 33(28):2000718

-

Zheng T, Pilla S (2020) Melt processing of cellulose nanocrystal-filled composites: toward reinforcement and cream nucleation. Ind Eng Chem Res 59(eighteen):8511–8531

-

Choque-Quispe D, Choque-Quispe Y, Ligarda-Samanez CA, Peralta-Guevara DE, Solano-Reynoso AM, Ramos-Pacheco BS, Taipe-Pardo F, Martínez-Huamán EL, Aguirre Landa JP, Agreda Cerna HW (2022) Effect of the add-on of corn husk cellulose nanocrystals in the evolution of a novel edible film. Nanomaterials 12:3421

-

Jeevahan J, Chandrasekaran M (2019) Influence of nanocellulose additive on the film backdrop of native rice starch-based edible films for food packaging, Recent Pat. Nanotechnol 13:222–233

-

Torlopov MA, Martakov IS, Mikhaylov VI, Krivoshapkin PV, Tsvetkov NV, Sitnikov PA, Udoratina EV (2018) Disk-like nanocrystals prepared by solvolysis from regenerated cellulose and colloid backdrop of their hydrosols. Carbohydr Polym 200:162–172

-

Worku LA, Bachheti RK, Tadesse MG (2022) Isolation and characterization of natural cellulose from Oxytenanthera abyssinica (Lowland Ethiopian Bamboo) using alkali peroxide bleaching stages followed by aqueous chlorite in buffer solution. Int J Polym Sci 2022:5155552. https://doi.org/ten.1155/2022/5155552

-

Miruts F (2020) On-farm demonstration of improved rice (Oryza sativa L) varieties in Pawe woreda of Metekel Zone, Federal democratic republic of ethiopia. J Biology, Agriculture and Healthcare 10:i–5

-

Ambawu T (2019) Value chain analysis of groundnut in Pawiworeda, Metekel Zone, Ethiopia. https://www.smile.com/certificate/505489. Accessed 28 Nov 2022

-

TAPPI (2002) Standards and suggested methods. TAPPI Printing, Atlanta, Georgia, U.s.a.

-

IUCN (1989) Policy statement on inquiry involving species at hazard of extinction. In: Canonical by the 27th Coming together of IUCN Council, Gland, Switzerland. https://portals.iucn.org/library/efiles/documents/PP-003-En.pdf

-

Xu Due west, Grénman H, Liu J, Kronlund D, Li B, Backman P, Peltonen J, Willför S, Sundberg A, Xu C (2017) Mild oxalic-acrid-catalyzed hydrolysis as a novel approach to set up cellulose nanocrystals. ChemNanoMat 3(ii):109–119

-

Beltramino F, Roncero MB, Vidal T, Torres AL, Valls C (2015) Increasing yield of nanocrystalline cellulose training process by a cellulase pretreatment. Bioresour Technol 192:574–581

-

Gong J, Li J, Xu J, Xiang Z, Mo L (2017) Research on cellulose nanocrystals produced from cellulose sources with various polymorphs. RSC Adv seven(53):33486–33493

-

Lu Q, Cai Z, Lin F, Tang L, Wang S, Huang BJ (2016) Applied science. Extraction of cellulose nanocrystals with a high yield of 88% by simultaneous mechanochemical activation and phosphotungstic acid hydrolysis. ACS Sustain Chem Eng four(4):2165–2172

-

Yu K, Yang R, Huang 50, Cao X, Yang F, Liu D (2012) Preparation and label of bamboo nanocrystalline cellulose. BioResources 7(2):1802–1812

-

Wijaya CJ, Saputra SN, Soetaredjo Iron, Putro JN, Lin CX, Kurniawan A, Ju YH, Ismadji South (2017) Cellulose nanocrystals from passion fruit peels waste as antibiotic drug carrier. Carbohydr Polym 175:370–376

-

Yu H-Y, Zhang DZ, Lu FF, Yao J (2016) New approach for unmarried-step extraction of carboxylated cellulose nanocrystals for their utilize as adsorbents and flocculants. ACS Sustain Chem Eng 4(five):2632–2643

-

Luzi F, Puglia D, Sarasini F, Tirillò J, Maffei K, Zuorro A, Lavecchia R, Kenny J, Torre L (2019) Valorization and extraction of cellulose nanocrystals from North African grass: Ampelodesmos mauritanicus (Diss). Carbohydr Polym 209:328–337

-

Yu H, Abdalkarim SYH, Zhang H, Wang C, Tam KC (2019) Simple process to produce loftier-yield cellulose nanocrystals using recyclable citric/hydrochloric acids. ACS Sustain Chem Eng 7(5):4912–4923

-

Saini A, Yadav C, Xue BL, Wang N, Dai 50, Li X (2019) Mixed-acid-assisted hydrothermal procedure for simultaneous preparation and carboxylation of needle-shaped cellulose nanocrystals. ACS Appl Polym Mater 2(2):548–562

-

Xie H, Zou Z, Du H, Zhang X, Wang X, Yang X, Wang H, Li One thousand, Li L, Si C (2019) Preparation of thermally stable and surface-functionalized cellulose nanocrystals via mixed H2SO4/Oxalic acid hydrolysis. Carbohydr Polym 223:115116

-

Li LB, Xu Westward, Kronlund D, Määttänen A, Liu J, Smått JH, Peltonen J, Willför S, Mu 10, Xu C (2015) Cellulose nanocrystals prepared via formic acid hydrolysis followed past TEMPO-mediated oxidation. Carbohydr Polym 133:605–612

-

Shanmugarajah B, Kiew PL, Chew IML, Choong TSY, Tan KW (2015) Isolation of nanocrystalline cellulose (NCC) from palm oil empty fruit agglomeration (EFB): preliminary effect on FTIR and DLS assay. Chem Eng Trans 45:1705–1710

-

Rehman Due north, de Miranda MIG, Rosa SM, Pimentel DM, Nachtigall S, Bica CI (2014) Cellulose and nanocellulose from maize straw: an insight on the crystal properties. J Polym Environ 22(2):252–259

-

Mondragon G, Fernandes Due south, Retegi A, Peña C, Algar I, Eceiza A, Arbelaiz A (2014) A mutual strategy to extracting cellulose nanoentities from unlike plants. Ind Crops Prod 55:140–148

-

Rasheed M, Jawaid One thousand, Parveez B, Zuriyati A, Khan A (2020) Morphological, chemic and thermal assay of cellulose nanocrystals extracted from bamboo fibre. Int J Biol Macromol 160:183–191

-

Bashar M, Zhu H, Yamamoto S, Mitsuishi Yard (2019) Highly carboxylated and crystalline cellulose nanocrystals from jute fiber past facile ammonium persulfate oxidation. Cellulose 26(6):3671–3684

-

Rayung M, Ibrahim NA, Zainuddin N, Saad WZ, Razak NIA, Chieng BW (2014) The effect of fiber bleaching treatment on the properties of poly (lactic acrid)/oil palm empty fruit agglomeration fiber composites. Int J Mol Sci 15(viii):14728–14742

-

Abdul Razak NI, Ibrahim NA, Zainuddin Due north, Saad RM, WZ, (2014) The influence of chemical surface modification of kenaf cobweb using hydrogen peroxide on the mechanical properties of biodegradable kenaf fiber/poly (lactic acid) composites. Molecules 19:2957–2968

-

Kondo T, Sawatari CA (1996) Fourier transform infra-crimson spectroscopic assay of the character of hydrogen bonds in baggy cellulose. Polymer 37(iii):393–399

-

Cheng M, Qin Z, Liu Y, Qin Y, Li T, Chen Fifty, Zhu Grand (2014) Efficient extraction of carboxylated spherical cellulose nanocrystals with narrow distribution through hydrolysis of lyocell fibers past using ammonium persulfate as an oxidant. J Mater Chem 2(2014):251–258

-

Jia Westward, Liu Y (2019) Two characteristic cellulose nanocrystals (CNCs) obtained from oxalic acid and sulfuric acid processing. Cellulose 26:8351–8365

-

Li D, Henschen J, Ek M (2017) Esterification and hydrolysis of cellulose using oxalic acrid dihydrate in a solvent-free reaction suitable for preparation of surface-functionalised cellulose nanocrystals with high yield. Green Chem 19:5564–5567

-

Bondancia TJ, de Aguiar J, Batista G, Cruz AJ, Marconcini JM, Mattoso LHC, Farinas CS (2020) Production of nanocellulose using citric acrid in a biorefinery concept: result of the hydrolysis reaction time and techno-economic analysis. Ind Eng Chem Res 59:11505–11516

-

Dong XM, Revol JF, Grey DG (1998) Event of microcrystallite preparation weather condition on the formation of colloid crystals of cellulose. Cellulose 5(ane):xix–32

-

Hu Y, Tang L, Lu Q, Wang South, Chen 10, Huang B (2014) Preparation of cellulose nanocrystals and carboxylated cellulose nanocrystals from borer powder of bamboo. Cellulose 221(3):1611–1618

-

Elanthikkal S, Gopalakrishnapanicker U, Varghese Due south, Guthrie JT (2010) Cellulose microfibres produced from banana plant wastes: Isolation and characterization. Carbohydr Polym 80(three):852–859

-

Seta FT, An X, Liu L, Zhang H, Yang J, Zhang W, Nie Due south, Yao S, Cao H, Xu Q (2020) Preparation and characterization of high yield cellulose nanocrystals (CNC) derived from ball mill pretreatment and maleic acid hydrolysis. Carbohydr Polym 234:115942

-

Li MC, Wu Q, Song K, Lee Southward, Qing Y, Wu Y (2015) Cellulose nanoparticles: structure– morphology–rheology relationships. ACS Sustain Chem Eng three(5):821–832

-

Yang X, Xie H, Du H, Zhang X, Zou Z, Zou Y, Liu West, Lan H, Zhang X, Si C (2019) Facile extraction of thermally stable and dispersible cellulose nanocrystals with loftier yield via a light-green and recyclable FeCl3-catalyzed deep eutectic solvent system. ACS Sustain Chem Eng 7(seven):7200–7208

-

Mohammed Northward, Lian H, Islam MS (2021) Potent Thou Shi Z, Drupe RM, Yu HY, Tam KC (2021) Selective adsorption and separation of organic dyes using functionalized cellulose nanocrystals. J Chem Eng 417:129237

-

Chen W, Yu H, Liu Y (2011) Preparation of millimeter-long cellulose I nanofibers with diameters of thirty–80 nm from bamboo fibers. Carbohydr Polym 86(2):453–461

-

Bhatnagar A, Sain One thousand (2005) Processing of cellulose nanofiber-reinforced composites. J Reinf Plast 24(12):1259–1268

-

Dos Santos RM, Neto WPF, Silvério HA, Martins DF, Dantas NO, Pasquini D (2013) Cellulose nanocrystals from pineapple leaf, a new arroyo for the reuse of this agro-waste. Ind Crops Prod 50:707–714

-

Tan XY, Abd Hamid SB, Lai CW (2015) Preparation of high crystallinity cellulose nanocrystals (CNCs) by ionic liquid solvolysis. Biomass Bioenergy 81:584–591

-

Cheng M, Qin Z, Hu J, Liu Q, Wei T, Li W, Ling Y, Liu B (2020) Facile and rapid one– footstep extraction of carboxylated cellulose nanocrystals by H2SO4/HNO3 mixed acid hydrolysis. Carbohydr Polym 231:115701

-

Roman Yard, Wintertime WT (2004) Effect of sulfate groups from sulfuric acrid hydrolysis on the thermal degradation behavior of bacterial cellulose. Biomacromol v(five):1671–1677

-

Liu C, Du H, Yu G, Zhang Y, Kong Q, Li B, Mu X (2017) Simultaneous extraction of carboxylated cellulose nanocrystals and nanofibrils via citric acid hydrolysis-a sustainable route. Newspaper and Biomaterials 2(four):19–26

-

Nascimento P, Marim R, Carvalho G, Mali S (2016) Nanocellulose produced from rice hulls and its effect on the properties of biodegradable starch films. Mater Res 19:167–174

-

Tonoli G, Teixeira Eastward, Corrêa A, Marconcini J, Caixeta L, Pereira-da-Silva M, Mattoso L (2012) Cellulose micro/nanofibres from Eucalyptus kraft lurid: preparation and properties. Carbohydr Polym 89(1):80–88

-

Wang R, Chen L, Zhu J, Yang R (2017) Tailored and integrated production of carboxylated cellulose nanocrystals (CNC) with nanofibrils (CNF) through maleic acid hydrolysis. ChemNanoMat 3(5):328–335

Author information

Authors and Affiliations

Contributions

All authors contributed to the study formulation and design. Material preparation, data collection, and analysis were performed by Limenew Allay Worku. The first draft of the manuscript was written by Rakesh Kumar Bachheti, Mesfin Getachew Tadesse, and Limenew Abate Worku. All authors commented on previous versions of the manuscript. All authors read and canonical the final manuscript. All authors also worked on revision of the article.

Respective writer

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's notation

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.chiliad. a guild or other partner) holds exclusive rights to this commodity nether a publishing agreement with the author(s) or other rightsholder(south); writer self-archiving of the accustomed manuscript version of this commodity is solely governed past the terms of such publishing agreement and applicable police.

Reprints and Permissions

Virtually this article

Cite this article

Worku, L.A., Bachheti, R.K. & Tadesse, One thousand.Yard. Preparation and characterization of carboxylated cellulose nanocrystals from Oxytenanthera abyssinica (Ethiopian lowland bamboo) cellulose via citric acid anhydrous hydrolysis catalyzed by sulfuric acid. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-022-03718-0

-

Received:

-

Revised:

-

Accepted:

-

Published:

-

DOI : https://doi.org/10.1007/s13399-022-03718-0

Keywords

- Carboxylated cellulose nanocrystals

- Mixed acids hydrolysis

- Characterization

- Oxytenanthera abyssinica

Source: https://link.springer.com/article/10.1007/s13399-022-03718-0

0 Response to "When Compared To Sulfuric Acid How Strong Are Carboxylic Acids"

Post a Comment